Vector Color Separation

- Home

- Vector Color Separation

Precision Technical Color Separation & Pre-Press

At High Rated Patch, we provide professional color separation services designed to bridge the gap between complex digital artwork and high-quality physical production. Whether you are preparing for screen printing, multi-color PVC molding, or high-fidelity textile printing, our process involves deconstructing your artwork into distinct, production-ready layers. We focus on chromatic accuracy and mechanical compatibility, ensuring that each color is isolated with surgical precision to guarantee vibrant, sharp, and cost-effective results.

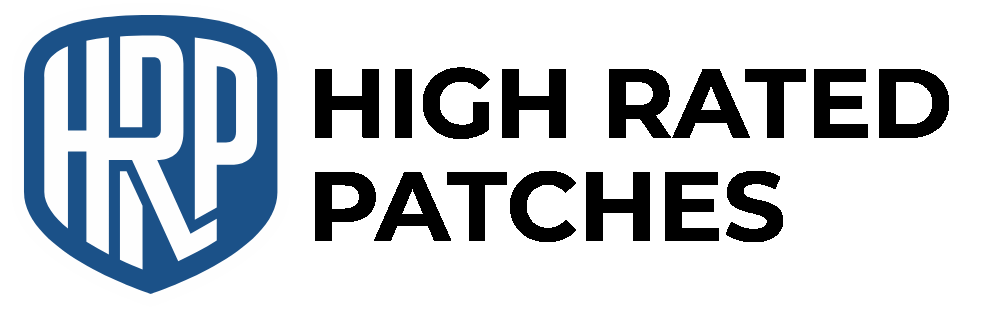

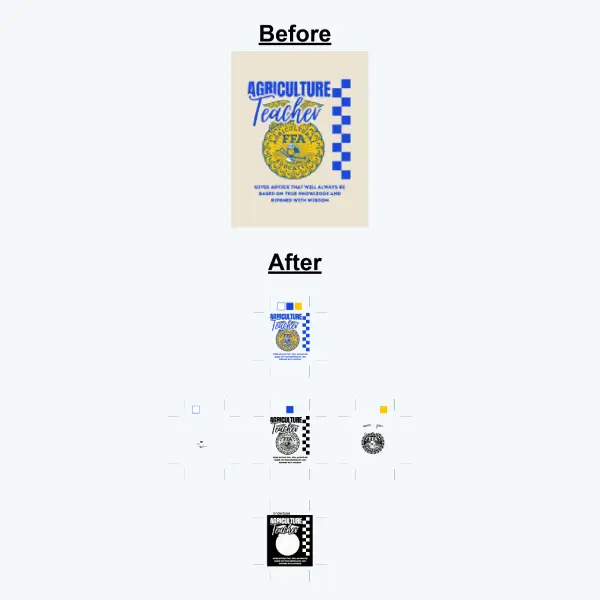

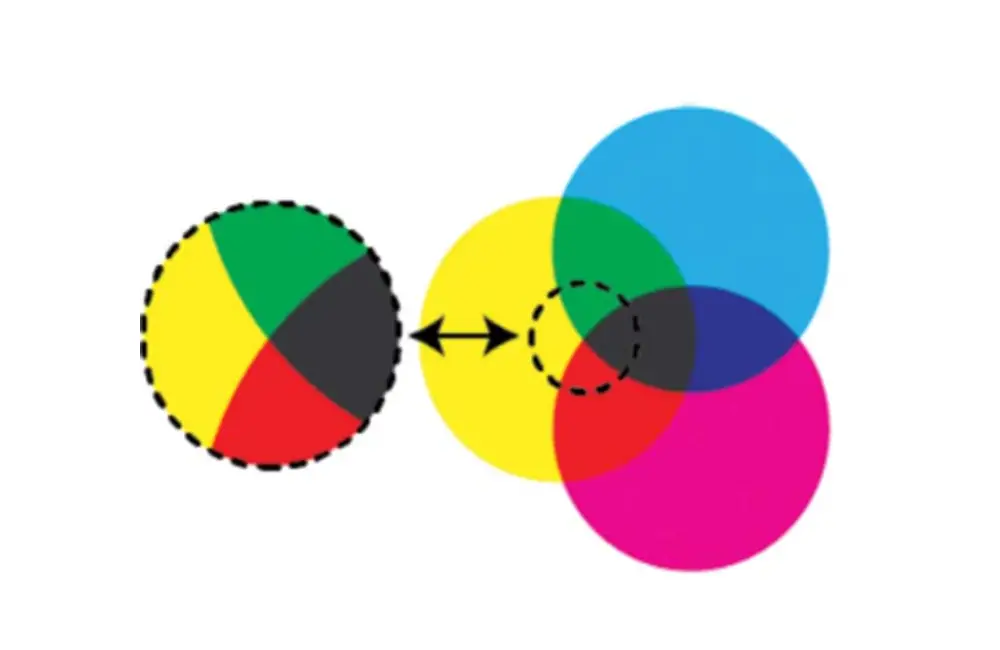

Our color separation is not a simple automated split; it is a technical audit of your design. We analyze ink opacity, substrate color, and manufacturing constraints to create a layering strategy that maximizes visual impact while minimizing production complexity and "press time."

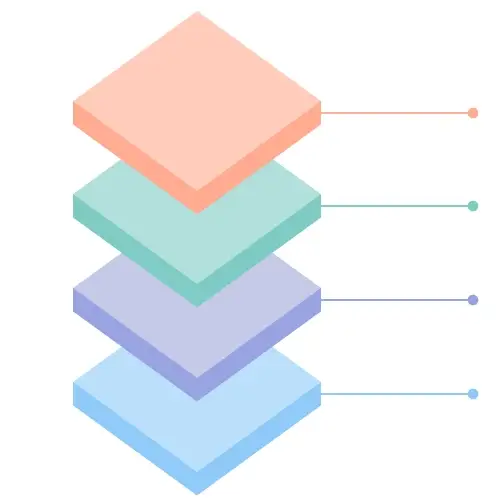

Strategic Layering & Underbase Engineering

The hallmark of a professional separation is the "Underbase." When printing on dark garments or substrates, we engineer a High-Opacity White Underbase that acts as a primer, ensuring that the top colors remain vibrant and true to their Pantone® references without being muted by the background material. By mathematically calculating the "choke" and "spread" of these layers, we eliminate alignment issues (registration errors), resulting in a flawless finished product.

Advanced Halftone & Process Logic

For designs containing gradients, shadows, or photographic elements, we utilize Advanced Halftone Screening. We convert continuous tones into a series of strategically sized dots, optimized for specific mesh counts or production resolutions. This allows us to replicate complex, multi-colored imagery using a limited number of physical ink stations or material colors, significantly reducing your manufacturing costs without sacrificing the integrity of the original art.

Technical Specifications & Features

Refine your brand assets with professional-grade file formats and design structures optimized for every industrial application.

- File Formats

- Design Features

AI (Adobe Illustrator)

The master source file. It preserves all live layers, paths, and metadata, serving as the primary blueprint for your brand’s future.

EPS (Encapsulated PostScript)

The universal production standard. Compatible with high-end industrial printers, vinyl cutters, and embroidery software.

SVG (Scalable Vector Graphics)

Optimized for the web. These files are lightweight and remain sharp at any zoom level on digital displays.

PDF (Vector-Embedded)

A universal, high-resolution viewing format that maintains all vector path data for easy sharing and proofing.

CDR (CorelDRAW)

Essential for many traditional manufacturing and embroidery setups globally, ensuring maximum software compatibility.

PNG/TIFF (High-Res)

We also provide transparent, high-DPI raster exports for immediate use in presentations and social media.

Global Pantone® Swatch Assignment

We assign specific Pantone Solid Coated codes to your paths to ensure 100% color consistency between your screen and the physical product.

Layered Path Architecture

Artwork is logically organized into color-coded layers, facilitating easy separation for screen printing or PVC mold injection.

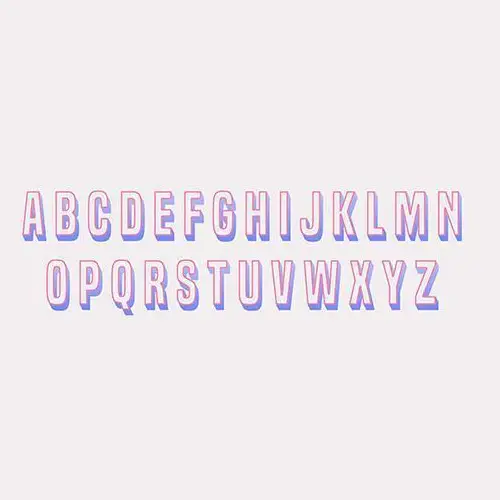

Typography Outlining

All fonts are converted into solid vector shapes, ensuring your branding remains intact even if the manufacturer does not have your specific font installed.

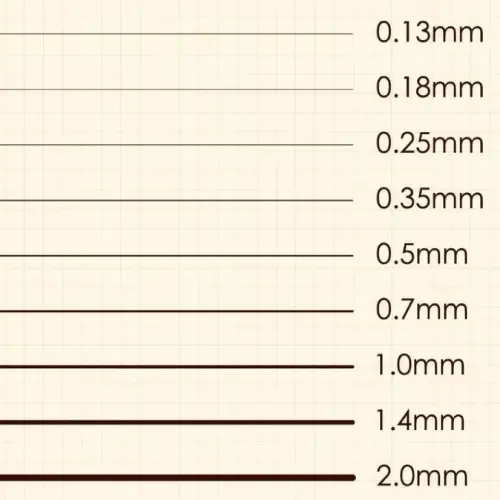

Line Weight Standardization

We ensure every line meets the 0.1mm minimum threshold required for physical production visibility.

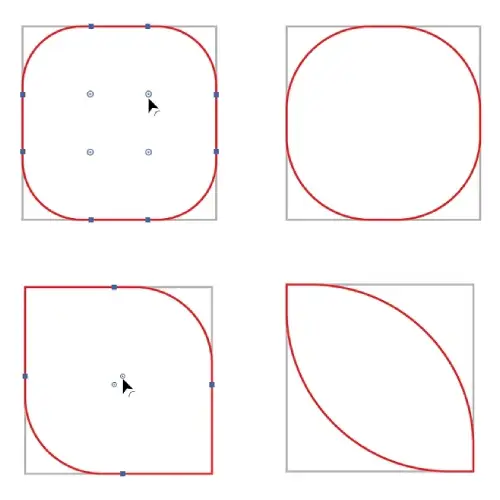

Anchor Point Optimization

We manually reduce redundant nodes, creating "clean topology" that allows manufacturing machines to run faster and smoother.

Negative Space Auditing

We optimize the gaps between elements to ensure they are wide enough to be rendered clearly in stitches or molded plastic.

Have Any questions?

Find answers to the most common questions about our vector color separation process and why it is critical for your brand.