Sublimation Patches

- Home

- Sublimation Patches

High-Definition Sublimated Printed Patches

At High Rated Patch, we create custom embroidered patches that embody professional quality and technical precision. We focus on meticulous stitch placement to ensure every design features sharp resolution, premium texture, and a high-end aesthetic for your brand.

Our products are engineered for longevity, utilizing industrial-grade threads and consistent stitching patterns to maximize your visual impact. These durable patches maintain their integrity and vibrant colors across workwear, team uniforms, and promotional headwear.

Whether you require minimalist logos or complex artwork, our production process guarantees results that reflect master-level craftsmanship and reliability for any professional application.

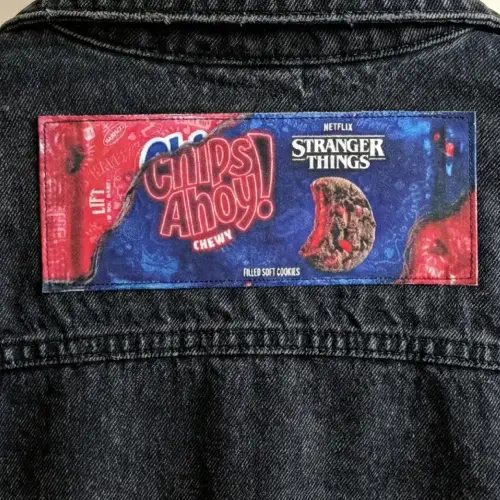

Molecular Dye-Infusion Technology

The sublimation process involves converting solid dye particles into a gas using controlled heat and pressure. These gaseous pigments penetrate the polyester fibers of the patch base and solidify within the material itself. Unlike screen printing, which sits on top of the fabric, sublimation becomes part of the fabric. This ensures a breathable, soft-touch finish that maintains the flexibility of the garment while providing 100% color saturation.

Limitless Color Spectrum

Sublimation removes the constraints of a physical thread palette. We can reproduce over 16 million colors, allowing for seamless transitions, glows, and photo-realistic imagery. This technology is ideal for brands that require exact replicas of digital artwork, ensuring that every highlight, shadow, and fine line is preserved with 300+ DPI (dots per inch) clarity.

Customize Your Patch

Multiple backing and border options to match your patch’s use and appearance.

- Backing Options

- Border Options

Sew-On Backing

A traditional, permanent method that ensures maximum durability for uniforms and heavy-duty apparel through direct stitching onto the garment fabric.

Iron-On Backing

A convenient and popular choice that allows you to apply patches easily using a standard heat press or household iron.

Adhesive Backing

A versatile, temporary solution perfect for events and short-term applications where patches need to be applied quickly without using heat.

Hook-and-Loop Backing

A two-part system designed for maximum versatility, allowing patches to be easily interchanged on tactical gear, uniforms, and specialized outerwear.

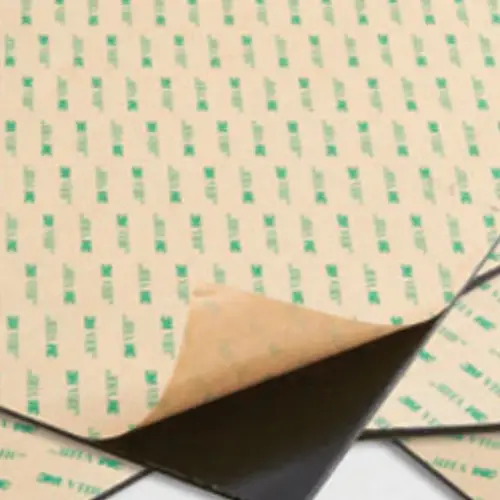

Peel-and-Stick Backing

An instant attachment method featuring a pressure-sensitive adhesive, ideal for one-time events, product launches, or temporary promotional branding needs.

Velcro Backing

A highly reliable, reusable backing that provides a secure grip while allowing for frequent repositioning on caps, bags, and professional uniforms.

Merrow Border

A classic, heavy-duty overlock stitch that creates a raised, rounded edge, providing a traditional finish ideal for standard shapes like circles, squares, and shields.

Heat-Cut Border

A precise finishing technique that uses heat to seal the edges of custom-shaped patches, effectively preventing fraying while maintaining a clean, sharp, and low-profile look.

Laser-Cut Border

An advanced manufacturing method using high-precision lasers to achieve intricate, complex shapes and internal cutouts that traditional cutting tools simply cannot replicate with such accuracy.

Stitched Border

A sleek and professional flat-stitch finish applied directly to the edge, perfect for thinner patches or designs requiring a modern, streamlined aesthetic on high-performance apparel.

Have Any questions?

Find answers to the most common questions about sublimation patches, including their types, uses, and customization options.