Left Chest Digitizing

- Home

- Left Chest Digitizing

Precision Branding for Professional Corporate Identity

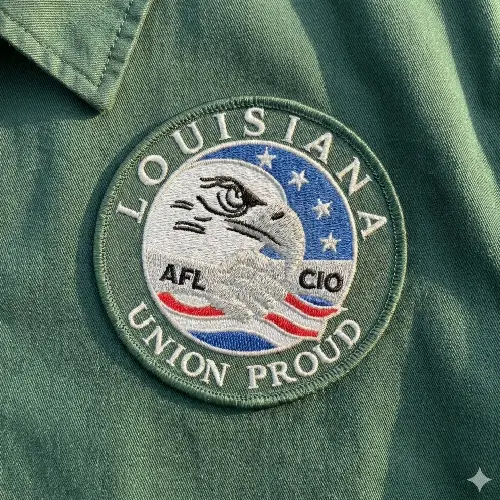

At High Rated Patch, we specialize in left chest digitizing—the industry standard for corporate uniforms, executive polos, and retail apparel. This specific discipline of embroidery requires a higher level of technical precision because it involves translating complex brand identities into a confined 3-inch to 4-inch workspace. We focus on micro-legibility and structural stability, ensuring that your logo remains crisp, flat, and professional across various garment types.

Our left chest digitizing process includes a Substrate Sensitivity Analysis. We don't use a "one-size-fits-all" file; instead, we engineer the stitch logic specifically for the fabric it will be applied to—whether it’s the textured weave of a pique polo, the stretch of a performance tee, or the heavy density of a softshell jacket.

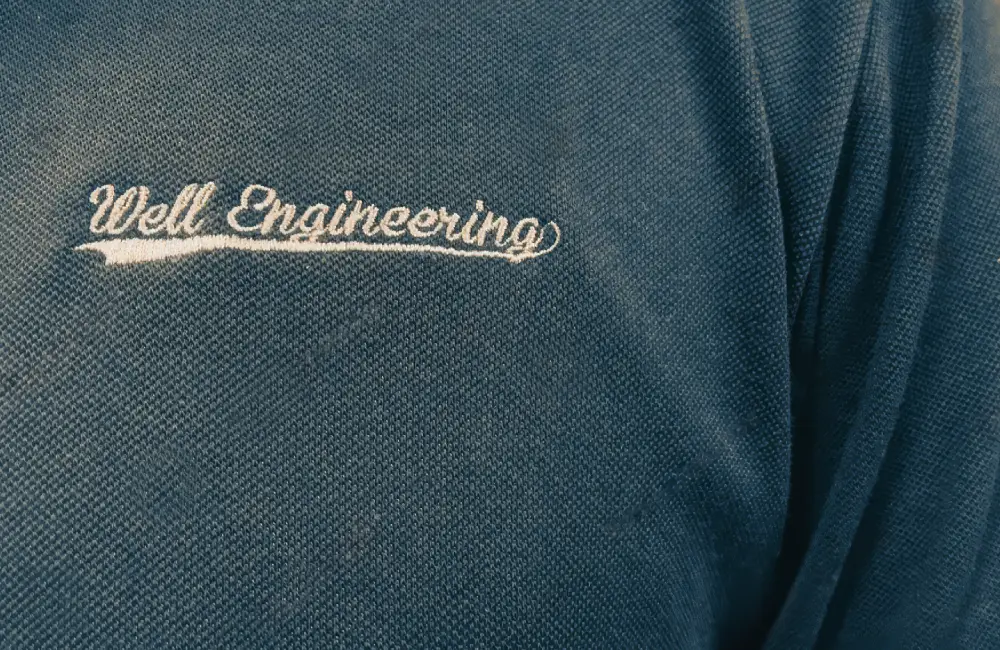

Micro-Text & Detail Clarity

The greatest challenge in left chest embroidery is rendering small taglines, URLs, and intricate logo elements. At High Rated Patch, we utilize Advanced Pathing Algorithms and specialized "thin-thread" logic to ensure that text as small as 4mm remains perfectly legible. We manually adjust the start and stop points of every letter to prevent "thread-clustering," resulting in a clean, retail-quality finish that enhances your brand’s perceived value.

Puckering Prevention & Stabilization

Left chest areas are prone to "puckering"—the unsightly wrinkling of fabric around the embroidery. Our engineers prevent this by utilizing Push-Pull Compensation and strategic Underlay Foundations. By laying down a stabilizing "skeletal" stitch before the top layers, we lock the garment's fibers in place. This ensures that even after multiple industrial wash cycles, your logo remains perfectly flat and aligned without distorting the garment's shape.

Technical Specifications & Features

Refine your brand assets with professional-grade file formats and design structures optimized for every industrial application.

- File Formats

- Design Features

DST (Tajima)

The universal industry standard for industrial embroidery machines. It contains all stitch and jump data without proprietary color locks.

PES (Brother/Baby Lock)

The primary format for many multi-needle and home-professional machines.

EMB (Wilcom Master File)

The "Source Code" of your design. It preserves all object properties, allowing for easy resizing and density adjustments.

PDF Production Worksheet

We provide a technical "spec sheet" including stitch counts, color sequences, and size dimensions for your production team.

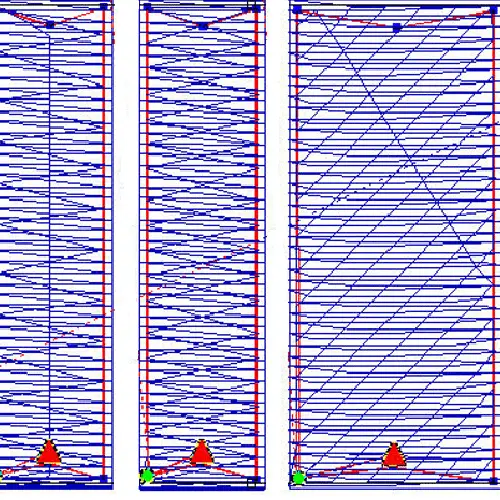

Custom Density Calibration

We adjust the number of stitches per millimeter based on the thread weight and fabric type to prevent "birdnesting" or fabric show-through.

Underlay Strategy

We engineer "foundation stitches" (center run, zigzag, or tatami) to stabilize the fabric and provide a 3D lift to the top stitching.

Automated Trim Reduction

We manually sequence the design to eliminate unnecessary thread trims, resulting in a cleaner finish and faster machine run-times.

Small Text Optimization

We utilize specialized "micro-stitch" settings for lettering as small as 4mm to ensure legibility and needle safety.

Satin vs. Tatami Mapping

We strategically assign Satin stitches for borders and high-gloss areas, and Tatami (Fill) stitches for large surface areas to balance texture and weight.

Appliqué Pathing

For large patches, we provide specialized "tack-down" and "cover-stitch" paths to integrate fabric inserts with embroidery.

Have Any questions?

Find answers to the most common questions about our embroidery left chest digitizing and production accuracy.